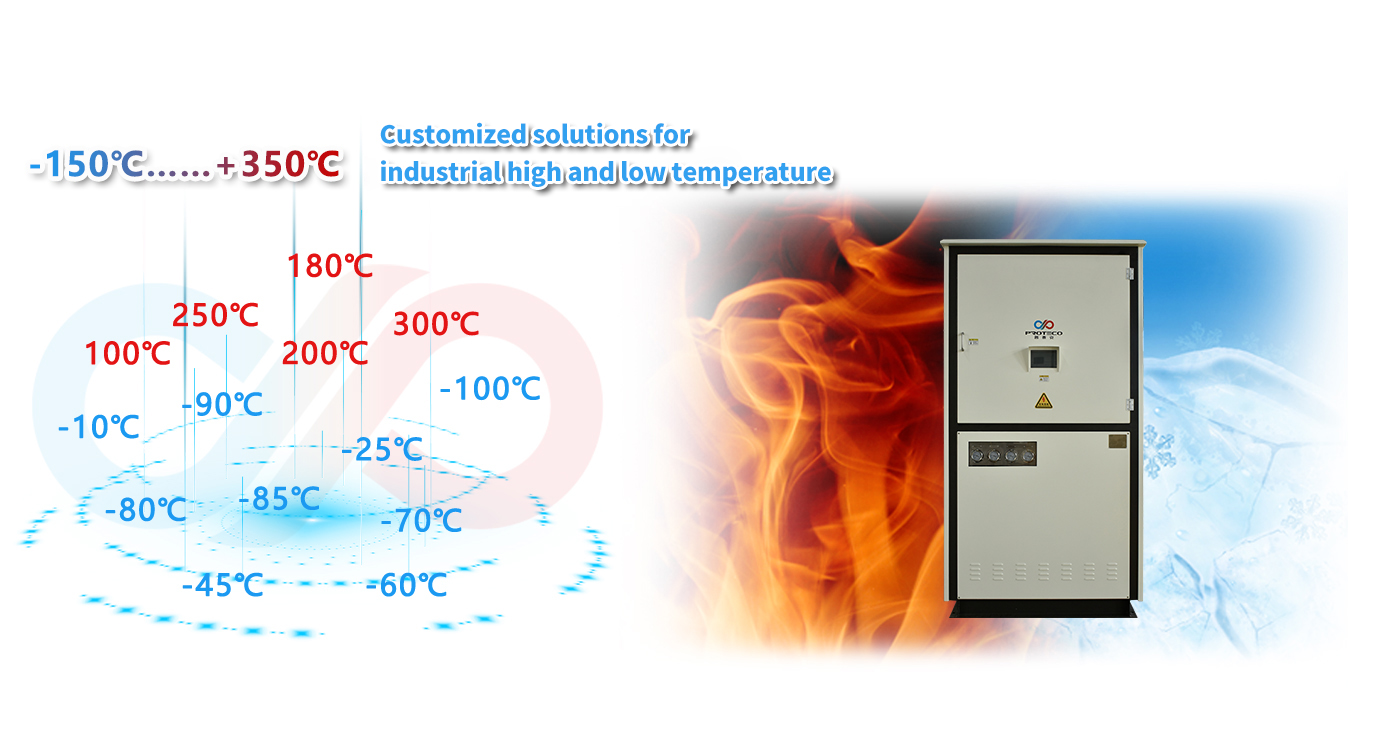

Probe station high and low temperature control system

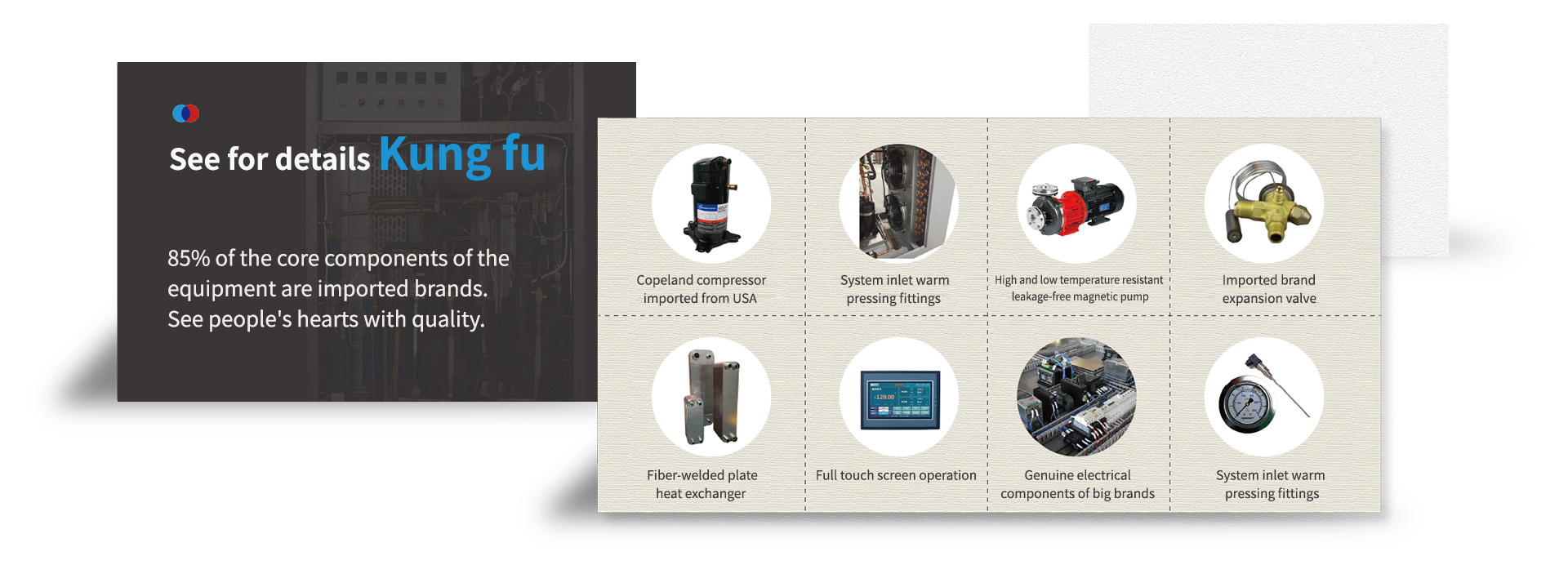

It mainly consists of heating circulation system, cooling system, control system, box, etc. The heating cycle system consists of a circulation pump, an electric heater, an expansion vessel, an exhaust valve, a one-way valve, a thermal resistor, and a circulation pipeline. The cooling system consists of oil-water heat exchangers, oil-oil heat exchangers (some equipment), cooling water solenoid valves, high-temperature solenoid valves, etc. The control system adopts PID control technology, high-definition touch screen display, and is equipped with multiple protection functions to ensure the safe operation of the equipment. By heating and cooling the unit itself, the heat carrying fluid is transported to the outside world to meet the requirements of the process conditions.

Fully enclosed system: Adopting a fully enclosed system design, the entire circulation pipeline only has breathing holes left on the filling cap, and the heat transfer oil will not directly come into contact with the air, extending the service life of the heat transfer oil while ensuring the stability of system operation. The expansion oil tank is always kept at room temperature and there is no oil mist generated at high temperatures.

Temperature control system: A self-developed temperature control module that changes the control setting method to quickly respond to system lag during the process and obtain the minimum temperature overshoot. The control consists of two sets of PID (each set of PID is variable) control loops, which become the main loop and the slave loop. The control output of the main loop serves as the set value of the slave loop. The system adopts a feedforward PV, and the output of the PID operation result of the main control circuit is combined with the feedforward PV signal as the set value of the main control circuit. By doing so, gradient control of temperature changes is carried out to ensure the temperature accuracy of the system.

Efficient heat exchange system: The system adopts pipeline heating and cooling, with very little liquid participating in circulation. Plate heat exchangers are used for refrigeration, and pipeline flange heaters are used for heating. The volume of the entire system (plate heat exchanger volume+pipeline heater volume+circulating pump internal volume+circulating pipeline volume).

Control repeatability: Based on advanced dynamic control systems, consistent control results can be achieved every time, greatly improving the stability of product production.

Product Appearance: The appearance design draws on the design concept of imported foreign products, using a large caliber quartz glass level gauge. The level gauge and operation screen are placed on the same side for easy observation, simple and fashionable style, coordinated layout, and exclusive color matching.

Ultra high temperature cooling technology: Adopting ultra-high temperature cooling technology, it can achieve rapid cooling by directly introducing cooling water at a maximum temperature of 350 ℃.

Consult immediately

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging