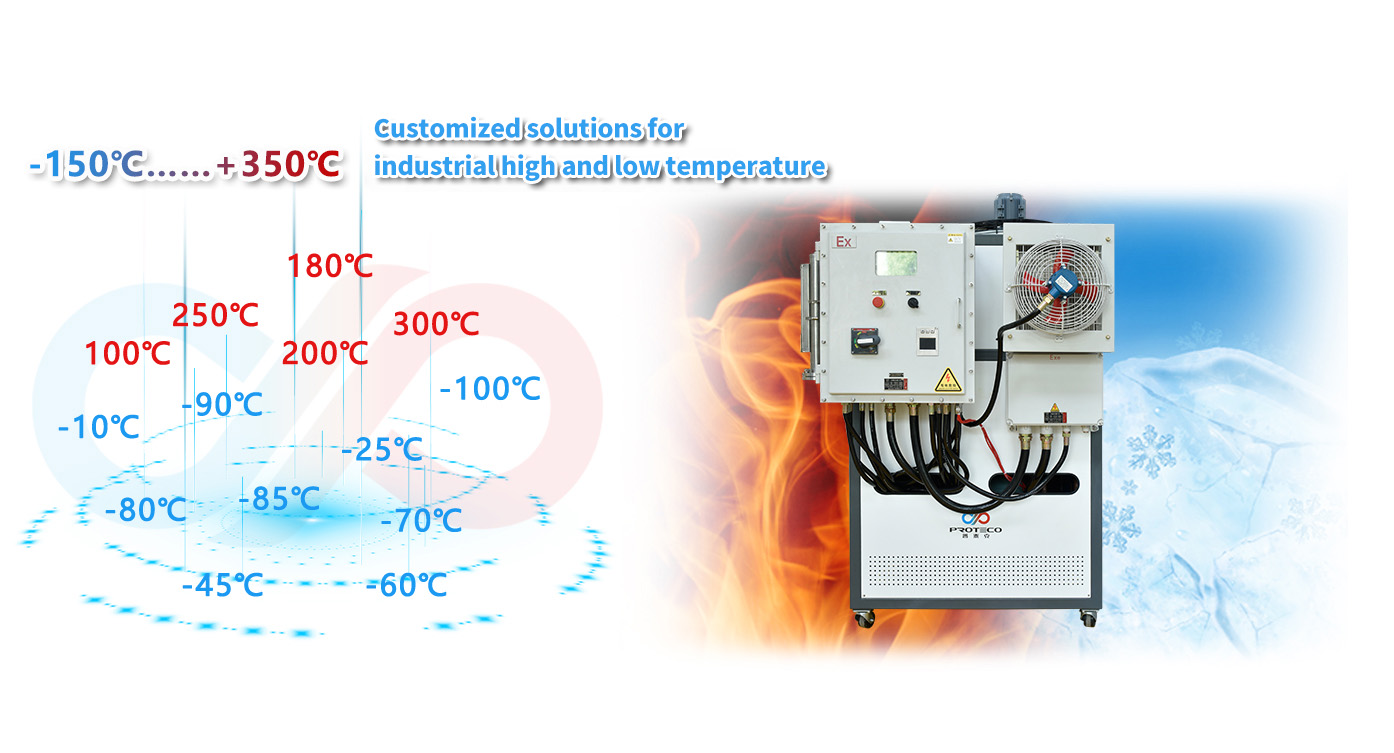

Carrier high and low temperature system

It mainly consists of refrigeration system, circulation system, control system, box, etc. The refrigeration system adopts steam compression refrigeration, and the compressor and main refrigeration components are all from internationally renowned brands. The circulation system consists of a circulation pump, electric heating pipes, expansion vessels, exhaust valves, one-way valves, thermal resistors, pipelines, etc. The control system adopts PID control technology, high-definition touch screen display, and is equipped with multiple protection functions to ensure the safe operation of the equipment. By cooling and heating the unit itself, the heat carrying fluid is transported to the outside world to meet the requirements of the process conditions. Suitable for external applications that require rapid heating and cooling, for temperature control and material testing of glass reactors, metal reactors, bioreactors, etc. It is particularly suitable for controlling processes that require heat and release during the reaction process.

1. Wide temperature control range, -110 ℃~+350 ℃ can be customized non-standard;

2. Adopting a fully sealed system, without oil mist or odor, the thermal conductivity liquid has a long service life;

3. There are very few thermal conductive liquids involved in the cycle, and the heating and cooling speed is fast;

4. Based on the advanced PLC controller, it can achieve dynamic control of material temperature throughout the entire process, with a maximum temperature control accuracy of ± 0.1 ℃;

5. Allow customization of non-standard control programs, such as output input points, communication methods and interfaces, alarm points, and customized operation interfaces as required;

6. Automatic exhaust function, built-in exhaust solenoid valve, no need for manual exhaust;

7. Detection and protection of outlet pressure of circulating pump;

8. Real time display of operating status, automatic diagnosis of fault information, and multiple alarm protection functions;

9. Controller IoT, which allows remote viewing of data, alarm information, and remote control on mobile apps;

10. Control repeatability: Based on advanced dynamic control systems, consistent control results can be achieved every time, greatly improving the stability of product production;

11. Adaptive PID control algorithm, facing different usage environments and loads, can achieve optimal temperature control without changing parameters;

12. Comprehensive security protection measures, with multiple security protection mechanisms in place to ensure the safe operation of the system;

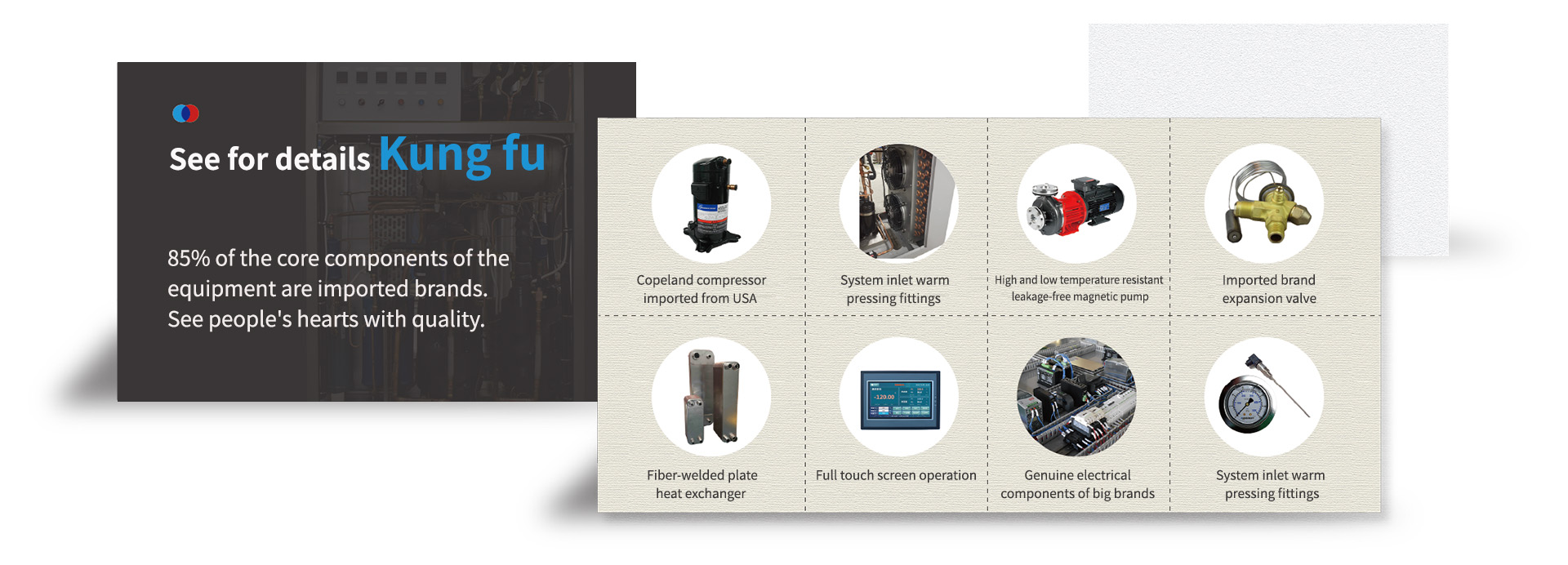

13. Quality assurance: All key components are selected from imported brands or domestic first tier brands to ensure long-term reliable operation of the products. At the same time, all products undergo strict testing and inspection before shipment to ensure that there are no problems with the equipment when it arrives at the customer's site.

Consult immediately

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging